Insecticide Resistance

Insecticide Resistance within mosquito populations is a global issue of increasing concern that must be addressed to protect public health (Insecticide Resistance Action Committee, https://irac-online.org/).

Insecticide Resistance within mosquito populations is a global issue of increasing concern that must be addressed to protect public health (Insecticide Resistance Action Committee, https://irac-online.org/).

Integrated Mosquito Management (IMM) involves the use of multiple methods to control mosquitoes based on an understanding of mosquito biology, the mosquito life cycle, and the way mosquitoes spread viruses. The use of chemicals to control mosquito populations is one of key components used for reducing risk of vector-borne disease transmission and consideration of chemical resistance in the local mosquito population should be taken into consideration. Knowing, understanding, and monitoring for chemical resistance should begin as early as possible in an IMM program. It is recommended that all IMM programs monitor their mosquito populations for resistance at the beginning of a season and as often throughout the season as thought necessary. Resistance data is most valuable when collected over time to allow for comparison and monitoring of trends. There are many methods to monitor the effectiveness of an insecticide, and program managers may need to adjust their approach from season to season.

The Centers for Disease Control and Prevention (CDC) defines that a population of mosquitoes is considered to be resistant to an insecticide if a mortality rate is less than 90%. So how would one know if they are working with an adult or larval mosquito population that has resistance?

For Adult Mosquitoes – the CDC Bottle Bioassay

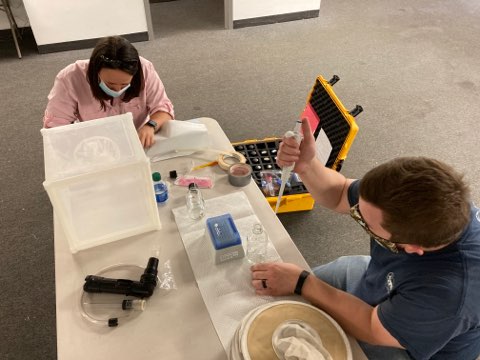

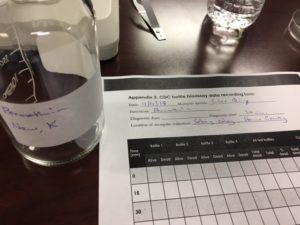

The most widely recommended and accepted practice for monitoring resistance to pesticides in mosquito populations is the CDC Bottle Bioassay. This method involves using mosquito eggs or larvae from the population of concern and rearing them to the adult stage. The study can also be completed by collecting adults from the field population. Once the adult mosquito population is ready to be tested, the inside of the testing bottles are coated with a dilution of the pesticide that is being tested and allowed to dry. There should always be at least two bottles that are only exposed to the drying agent (usually acetone) and these bottles will be labeled the “Control” group. Having a control group allows for the demonstration of proper handling techniques of the mosquitoes.

The most widely recommended and accepted practice for monitoring resistance to pesticides in mosquito populations is the CDC Bottle Bioassay. This method involves using mosquito eggs or larvae from the population of concern and rearing them to the adult stage. The study can also be completed by collecting adults from the field population. Once the adult mosquito population is ready to be tested, the inside of the testing bottles are coated with a dilution of the pesticide that is being tested and allowed to dry. There should always be at least two bottles that are only exposed to the drying agent (usually acetone) and these bottles will be labeled the “Control” group. Having a control group allows for the demonstration of proper handling techniques of the mosquitoes.

Once the chemicals in the bottles have dried completely, the adult female mosquitoes are added to each of the bottles. The control mosquitoes go through all of the stresses that each other set of mosquitoes must endure, except for actual exposure to the chemical being tested. Mortality counts are taken in 15-minute increments until all mosquitoes are dead or 2 hours, whichever comes first. Once the CDC Bottle Bioassay tests have been run, the data is then graphed to show the level of resistance, if any. The formulas for the chemical dilution as well as the guidelines for handling adult mosquitoes from the field, to help ensure that the population is healthy at the time of testing, can be found on the CDC website.

For Larval Mosquitoes – Larval Cup Bioassay

Larviciding is one of the primary means by which mosquito control agencies reduce mosquito populations. While resistance to larval control agents is less common than those used for controlling adult populations, it is still important that we ensure the intended results of any pesticide application.

Larval mosquito control products can work by ingestion or contact with the target host. Types of larval mosquito control agents that are routinely tested using the cup bioassay include bacterial larvicides like Bacillus thuringiensis israliensis (Bti), Bacillus sphaericus (Bs) or Spinosad which must must be ingested by mosquito larvae. S-methoprene is an example of a larval mosquito control agent that requires contact with the target mosquito and would need to be tested with an emergence chamber.

To learn more about each of these resistance testing strategies check out the videos provided by the Pacific Southwest Centers of Excellence in Vector-Borne Diseases. (https://pacvec.us/larval-mosquito-resistance-testing-video/).

Is it Possible to Use a Chemical Routinely and NOT Observe Resistance?

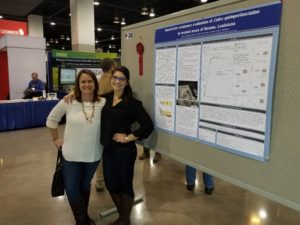

The great new is, it is! A research project on the topic was recently completed at one of our contracts in the Delta region of Louisiana. After eight (8) years of using the suggested mid-label rate of application for the insecticide resmethrin, followed by nine (9) years of mid-label rate applications of the insecticide permethrin in Ruston, LA, local Culex quinquefasciatus eggs were collected and sent to the CDC lab in Fort Collins, CO. The CDC reared the eggs to the adult stage and ran CDC Bottle Bioassays using the chemicals resmethrin and permethrin. The results showed no signs of resistance with a mortality rate of 100% at 30 minutes. The Ruston example was a piece of a larger research project lead by the CDC.

The great new is, it is! A research project on the topic was recently completed at one of our contracts in the Delta region of Louisiana. After eight (8) years of using the suggested mid-label rate of application for the insecticide resmethrin, followed by nine (9) years of mid-label rate applications of the insecticide permethrin in Ruston, LA, local Culex quinquefasciatus eggs were collected and sent to the CDC lab in Fort Collins, CO. The CDC reared the eggs to the adult stage and ran CDC Bottle Bioassays using the chemicals resmethrin and permethrin. The results showed no signs of resistance with a mortality rate of 100% at 30 minutes. The Ruston example was a piece of a larger research project lead by the CDC.

Overcoming a Resistant Population

However, once resistance has been identified, there are a few management methods to address the problem that will allow for continued control of the resistant mosquito population.

Management by Moderation. This method is meant to maintain the susceptible genes in the overall mosquito population by using low insecticide rates, infrequent applications, and non-persistent compounds.

Goal: Genetically speaking, you are trying to give the local population a chance to “recover.”

Management by Saturation. The approach is just as it sounds. The population is saturated with sufficient doses so that no survivors remain. This method can be especially useful during the early stages of selection of resistant genes.

Goal: To put a break in the resistance and not let it continue to the next generation.

Management by Class Rotation. An additional option, for continuing to successfully manage a mosquito population with known chemical resistance, is to change to a different class of chemical that uses a different Mode of Action (MoA). There are many EPA approved pesticides available for the use of mosquito control. However, there are limited classes of chemicals – only three (3). This is important because each class of chemical has a unique MoA, which is the method of interrupting a mosquito’s vital processes that result in its death. But with only three options available, and typically a significant price increase between classes, it is important that this method is used responsibly.

Goal: To prevent further growth of resistance in a population by introducing a chemical that has an alternative process to attack the mosquito’s body functions and result in death.

Potential Resistance Phenomena

Sometimes IMM programs will run into additional resistance problems that can further convolute treatment plans.

Sometimes IMM programs will run into additional resistance problems that can further convolute treatment plans.

Cross Resistance means that the population is not only resistant to one insecticide of a particular class, but also to other insecticides in the same class, even when that population has never been treated with that insecticide.

Multiple Resistance refers to separate detoxification mechanisms for unrelated insecticides are present resulting in a mosquito population that is resistant to different classes of insecticides (with different mode of action) which makes chemical control of that population extremely difficult.

Behavioral Resistance. There is also documentation of a phenomenon called Behavioral Resistance where mosquitoes have been found to no longer rest on surfaces that have been treated with a residual adulticide chemical in the past.

What happens if you ignore the problem?

Insecticide resistance is an inevitable result of overuse/reliance on a single class of insecticides and compromises efforts to control mosquitoes. Continued use of pesticides in moderately susceptible populations can result in the selection of resistant individuals and the loss of chemical sensitivity in certain areas. The use of chemicals that are not successful in controlling mosquito populations during a disease outbreak situation can result in wasted time, wasted resources, and an increased burden to society through human disease transmission.

Advice: Monitor, Monitor, Monitor

Resistance is not a new concern in the mosquito management industry. However, it is possible to minimize the occurrence of resistance if the chemicals are applied responsibly and the local mosquito population is tested regularly in an attempt to detect resistance in the earliest stage possible. As mosquito control professionals, the top priority of mosquito management is to be effective at protecting the public from the many vector-borne diseases that are transmitted by mosquitoes. In order to maintain our ability to do so, we must be familiar with chemical resistance levels and be proactive in addressing resistance once found. Monitoring for chemical resistance is just one of the many components of a successful Integrated Mosquito Management Program, but it is an important one that should not be overlooked.

Resistance is not a new concern in the mosquito management industry. However, it is possible to minimize the occurrence of resistance if the chemicals are applied responsibly and the local mosquito population is tested regularly in an attempt to detect resistance in the earliest stage possible. As mosquito control professionals, the top priority of mosquito management is to be effective at protecting the public from the many vector-borne diseases that are transmitted by mosquitoes. In order to maintain our ability to do so, we must be familiar with chemical resistance levels and be proactive in addressing resistance once found. Monitoring for chemical resistance is just one of the many components of a successful Integrated Mosquito Management Program, but it is an important one that should not be overlooked.

VDCI is committed to public education and spreading awareness throughout the U.S. about the dangers of mosquito-borne diseases and their preventability. Our dedicated and experienced team work tirelessly to prevent the spread of mosquito-borne diseases in all of the contracts we service. If you would like more information about any aspect of an Integrated Mosquito Management (IMM) Plan, including mosquito surveillance, insecticide resistance testing, disease testing, adult control, or aerial applications, please contact Vector Disease Control International (VDCI), and we will help you get started immediately.